Industrial cleaning wipes are a simple yet efficient solution to immediate workplace hygiene. However, there are many wipes in the market, each suitable for their line of work. This is why knowing your wipes and your industry is essential. Industrial wipes should be lint-free and abrasion and tear-resistant. Add that to a high releasing and absorbing ratio, and you're good to go.

Finally, industrial wipes should be well-suitable for their task. The number of industrial wipe manufacturers in the international market is blooming. Out of these, it's only natural that certain types of industrial wipes are specific to certain types of industries.

What Are The Different Types of Fiber Used in Industrial Wipe Production?

Two different types of wipes occupy the international market. Each of these wipes has its advantages and disadvantages. However, regarding industrial usage, only one wipe reigns supreme. The wipes in question are of the nonwoven type. Let's examine why industrial nonwoven wipes are much more common than woven ones.

Nonwoven vs. Woven Fiber

Nonwoven industrial wipes are undoubtedly any employer's first choice. That isn't to say, however, that woven wipes are useless. Both types have qualities that make them suitable for different situations.

Woven fiber is used to make some of the cleanest wipes around; They're perfect for making cleanroom wipes and are made by looping monofilament or continuously knitting. Knitted fiber is highly durable and is also used in heat sealing.

Woven fiber is not suitable for an industrial setting despite its benefits. Nonwoven fiber is the primary material used to make industrial wipes. There are many reasons why, for instance:

- These wipes are made by bonding short and long fibers together.

- Nonwoven industrial wipes are great at absorbing aqueous solutions and solvents too.

In comparison to woven wipes:

- Nonwoven wipes leave behind no residue, such as lint, etc.

- They are very economical and provide almost the same benefits as woven ones.

- These wipes are much better at dealing with harsh chemicals and grease etc.

For these reasons, nonwoven fiber is the primary choice for industrial wipes.

What Are Some Common Fibers Used In Industrial Wipe Production?

Industrial wipes are rarely made from a single material. Industrial wipes are usually a mixture of different nonwoven fabrics. Other types of fibers have different properties. As such, during production, they're mixed in different ratios.

Depending on the type you want, these ratios can vary. Let's take a household wipe, for instance. It'll have a blend more suited to strength and absorption than softness.

With that being said, let's take a look at the different types of nonwoven fiber:

1) Polyester and Polyamide

A majority of industrial wipes are made using polyester and polyamide fabrics. Wipes made of these fabrics have excellent tear and abrasion resistance. Leaving aside their dry strength, even their wet strength is nothing to scoff at.

Polyester wipes have a good recovery, heat setting, and high elasticity. However, they may accumulate static charge from time to time.

2) Cotton

Cotton is another (less commonly) used fabric. It has high bulk, a cheap cost, good strength, and a high drape. However, they have their fair share of drawbacks.

Cotton wipes have a non-elastic recovery and a meager resistance to soiling.

3) Viscose Filament

This fiber has little to no pilling and a good drape. They tend to clean quickly and are comparatively cheaper than the other fiber.

However, wipes made from viscose filament tend to fail. Especially when they're met with wet or abrasive substances, they also have a rigid handle and are slow dryers compared to other industrial wipes.

4) Wool

Wool has excellent absorption with high elasticity. They bulk pretty well, have an easy handle, and quick recovery. However, their prices can fluctuate wildly. Not only that, but they're relatively weaker than other fibers and have a higher shrinkage.

What Are The Best Industrial Wipes? (And How To Buy Them)

The best industrial wipes must have a particular set of qualities. These qualities will make them perfect for an industrial setting and everyday use. Not every type of industrial wipe has the same characteristics.

Different industries have to combat different situations. Therefore, you must consider the industrial wipes you need before buying. With that being said, the best industrial wipes will have these four major factors in common:

1) Tear Resistance

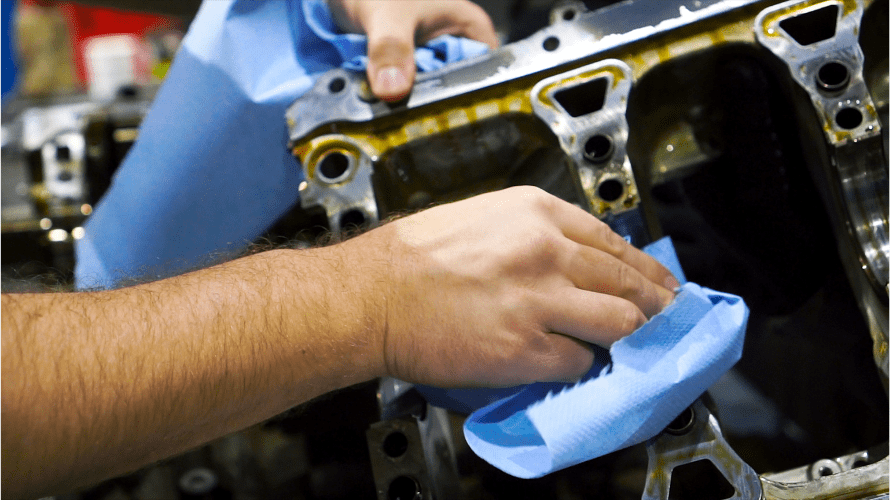

Another excellent quality is that the best industrial wipes have tear resistance. Tear resistance is the ability to avoid tearing against sharp edges and mechanical stress.

Industrial wipes are geared toward heavy-duty work and cleaning. Any industrial wipe worth its salt must be capable of handling such situations.

The good part is that most nonwoven industrial wipes are made of polyester or polyamide. These materials are famed for making some of the most robust industrial wipes.

2) Lint-Free Capabilities

For those unaware, lint is the fiber residue left behind on surfaces after cleaning. While industrial wipes are, for the most part, made of nonwoven fabric, you can never be too sure to check!

Lint residue can leave a Foreign Object Debris (FOD) risk. A FOD risk can hinder the working process after cleaning. For instance, critical cleaning operations (CCO) like fuel tank cleaning must be carried out repeatedly if a FOD risk prevails.

Even non-critical operations must only have a small amount of lint after cleaning. Let's take a piece of electronic equipment as an example. If left uncontrolled, the equipment can accumulate charge due to the lint. This charge continues to accumulate until it eventually causes damage to the equipment.

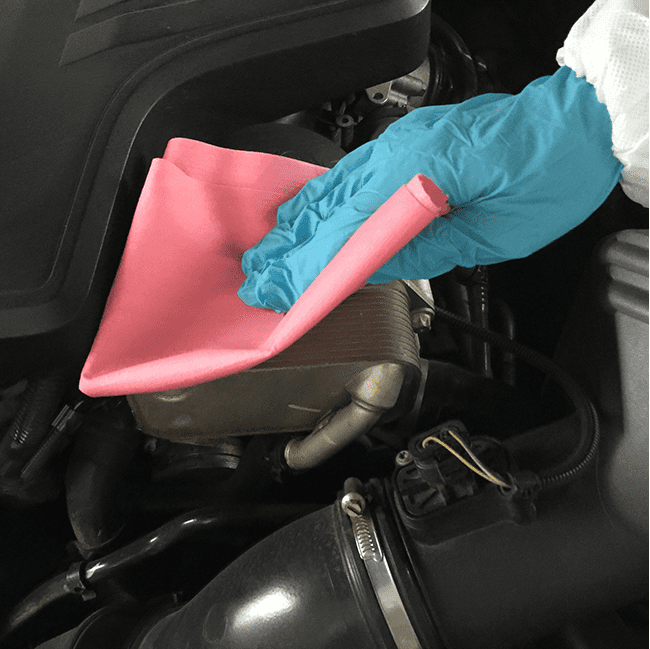

3) Releasing and Absorption Capacity

Absorbing a solution and then releasing it are critical characteristics of any wipe. When it comes to industrial wipes, these are essential. Above all, industrial spills need to be cleaned up thoroughly and promptly.

A wipe with a more significant absorption rate cleans much more quicker. Releasing is a little different. It is the amount of cleaning solution released by the wipe during cleaning.

Nevertheless, an excellent wipe will have high absorption and release quality.

4) Abrasion Resistance

You can think of abrasion resistance as a more evolved form of tear resistance. Tear resistance is straightforward; abrasion resistance is a bit vague. After all, abrasion resistance targets the wipe's ability to deal with different surfaces.

A good abrasive cleaning cloth (or wipe) is meant for a wide range of surfaces. Spills can occur on any surface in an industrial setting, from rough ground to a smooth counter.

A high abrasion resistance promises the fact that the wipe won't fall apart on rugged surfaces. Nonwoven wipes made of polyamide have the best abrasion resistance (mainly due to their fiber strength and construction).

Where And How to Get The Best Industrial Wipes?

In this day and age, the best products aren't limited to a specific country. Much less those with such everyday use, such as industrial wipes. You can get industrial wipes from almost anywhere, from online brands to local stores.

The only problem, however, is choosing the best ones out of all the different products available. How do you make the best choice for yourself out of all the other available products?

The first thing is knowing your industry and the cleanups that come with it. For instance, production lines usually require industrial wipes for grease.

Once you know what you'll be dealing with, it's time to move on to finding your industrial wipes. Different industrial wipes have different characteristics.

For instance, a non-abrasive wipe is used in more delicate industries. These wipes are used to disinfect surfaces that require more care, like glass. You can also think of them as antibacterial wipes.

On the other hand, let’s look at embossed (or aperture) wipes. These wipes have a rugged surface and are generally aimed for sealant removal. They're perfect for grease and other heavy adhesives and are common in industries.

Lastly, microfiber wipes are the best at picking dust and soil. With such a variety, knowing what you need can make a difference. After all, an excellent wipe meant for a delicate task won't help much with grease.

Finally, you have to ensure that your wipe has all the four qualities mentioned previously.

Conclusion

Not all industrial wipes are made out of the same fiber. There are two main types of fibers, woven and nonwoven fiber when it comes to wipes. In an industrial setting, however, nonwoven fiber seems to be the preferred one.

This is because nonwovens leave behind little to no lint residue. Furthermore, they're better at absorbing different solvents and harsh chemicals. However, even nonwovens are further divided into different types of fiber.

Industrial wipes are a mixture of different types of fibers. These include polyamide, polyesters, wool, cotton, and viscose filaments. They each have their pros and cons and are suited for various situations.

Depending on the type of wipe, the percentage of one fiber may be higher than the other. Other than that, an excellent industrial wipe must have a few qualities. This includes:

- No lint residue.

- A good absorption-to-release ratio.

- A superb abrasion and tear resistance.

It doesn't matter where you source your wipe from. Making sure that they meet the above criterion makes them the best for you.