Industrial cleaning is a big business. It's not just about making your workplace look nice, though.

Industrial cleaning also helps protect against accidents, keeps your equipment operating at peak performance, and enables you to avoid costly downtime.

If you've ever wondered how to do industrial cleaning properly, we're here to help!

We'll show you a few tips for ensuring that your workers get the most out of their time in the office—and maybe even learn a few tricks along the way.

How To Do Industrial Cleaning?

Industrial cleaning involves various steps, including regular inspection and cleaning of industrial equipment and machinery, cleaning of industrial carpet, sanitization of most-touched areas, cleaning loading docks, dusting windows and ceilings, an inspection of the exhaust system, removal of any flammable or corrosive materials, and finally neutralize any odors or residues left during cleaning.

Still unclear about the right procedure to undergo industrial cleaning? Don't Worry! Keep on reading as we will discuss the cleaning process in detail.

What is industrial cleaning?

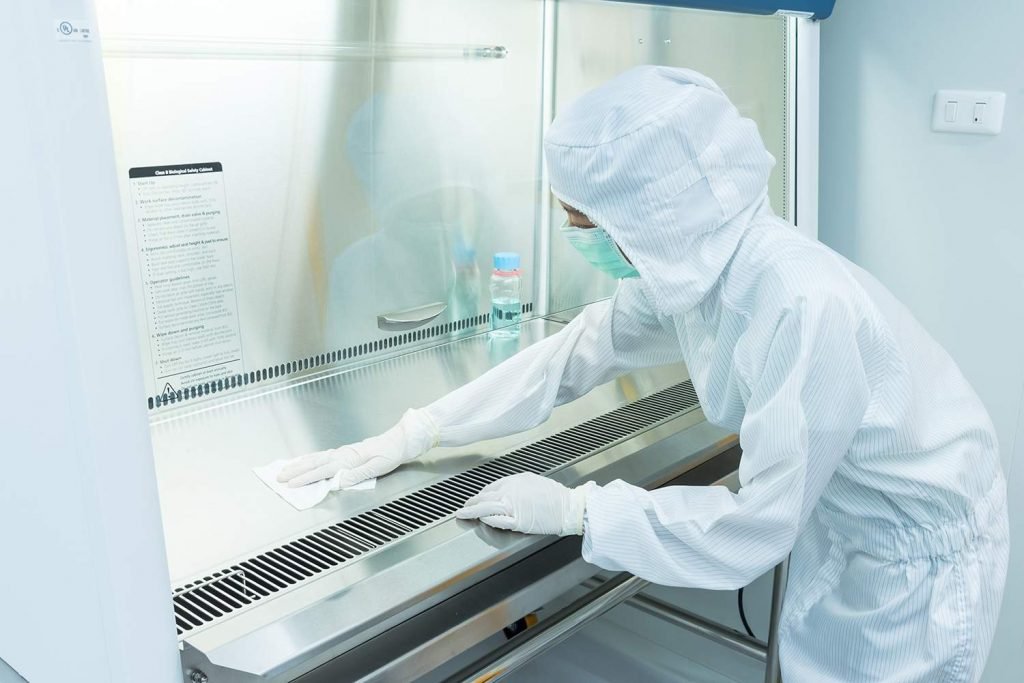

Industrial cleaning is a process that involves the use of chemicals and other materials to clean industrial equipment.

It can be used for interior and exterior machinery surfaces, and it's often used to clean equipment that already has a coating on it. In some cases, this coating may be damaged or worn out, leading to corrosion issues that are difficult to solve with regular cleaning methods.

Besides the industrial equipment, chemicals and other materials like cleaning wipes are also used to clean the surroundings of the industrial equipment, including doors, floors, carpets, ceilings, lights, walls, windows, ventilation systems, water pipes, etc.

Industrial cleaning is indeed a hectic job, but the correct procedure and planning, along with trained professionals and efficient cleaning material and equipment, can make it much easier.

Industrial Cleaning Best Practices:

The following industrial cleaning best practices will help you optimize the effectiveness of your cleaning process and lower your operation’s footprint to reduce costs while maintaining quality at the same time:

You can follow the steps under for the most effective cleaning:

1. Identify the most critical path for cleaning:

You need to identify which path needs the most attention and cleanliness. By knowing this, you can focus your cleaning efforts on that path.

Many factors can help you identify the most critical path for cleanliness. For example, the types of machines your plant operates. If you have sensitive equipment in your facility, you should consider the most critical approach for the cleanliness of these machines and their surroundings.

2. Identify where you can do without cleaners:

Once you have identified the most critical path for cleaning, you can determine what you can do without professional cleaners.

First, you must define what you mean by "do without cleaners." You can't just cut the budget for cleaners or expect the same results when you do it this way. Instead, you need to create a standard operating procedure (SOP) for every task your cleaners currently perform.

Create an SOP for every task your cleaners currently perform and ensure that what is expected is clear. Once you have created an SOP for every task, you can then determine where you can do without cleaning services.

3. Remove Dust:

Don't let the dust settle on the machinery and its surrounding. This will increase the equipment's life, reduce maintenance costs, and ease the industrial cleaning process.

You must deploy cleaners to regularly remove the dust from the surface of the machines and equipment as well as doors, windows, floor, and ceiling. This can be done using specialized microfiber cloths and cleaning wipes. And for the machinery surfaces that have oil, you can use oil absorbent wipes and sheets.

There are several other ways to remove dust from industrial facilities:

- Sprinkler System: They are effective for removing dust from surfaces and carpets. They're also very simple to set up and can be operated with remote control.

- Dust Collector: Dust collectors are handy for removing large quantities of dust. They're relatively expensive, but they can be used in various settings. For example, they can be used to remove dust from warehouses.

4. Wash Surfaces:

The key to washing surfaces is to ensure that they're entirely free of dust before you use any cleaning products. This can be difficult if there is a significant accumulation of dust, but it's essential if you want to prevent harmful bacteria from building up.

The best way to wash surfaces is to use a high-pressure water system controlled by a computer. This type of system is more advanced and will ensure that the water pressure is evenly distributed over the surface of the equipment. This is important because it helps to prevent damage to the machine. Furthermore, it prevents dirt from being removed.

Alternatively, you can use a pressure washer to wash surfaces. Pressure washers are available in different sizes and are convenient to use. However, they’re not as effective as high-pressure systems and can damage surfaces.

Once washed, it is critical to dry the surfaces. You can do this with Absorbent industrial wipes or multipurpose cleaning wipes to absorb water residue. This residual water can cause corrosion or rust if not cleaned.

5. Disinfect:

A disinfectant is a great way to disinfect surfaces that have been washed. Disinfecting a surface will prevent harmful bacteria from growing on it, which will help to prevent the spread of infections.

You can use disinfectants to disinfect equipment, surfaces, and even the air. There are different types of disinfectants that you can use, including iodine-based products and products that contain ultraviolet light.

These will kill all types of bacteria, including harmful ones that may be present in the environment.

Some disinfectants are applied on the surface and wiped using microfiber clothes.

6. Remove Odors and Improvise

If your industrial facility has an unpleasant odor, you may wish to consider attempting to remove it.

To do so, you can use a deodorizer to mix it with water, then spray it on surfaces. You can later clean the surface with multipurpose cleaning wipes.

You can also use an air deodorizer to scrub the air of any unwanted odors.

You can also try to improvise the odor source in your industrial facility. For example, you can try to remove the source of the odor by cleaning the equipment.

7. Maintain

It's crucial to maintain industrial cleaning equipment so they don't become clogged and must be repaired.

If you are not maintaining your equipment, it will begin to break down and become unusable. Furthermore, it will also become more challenging to keep your facility clean.

Some other Industrial cleaning best practices include:

- Minimize the use of toxic chemicals.

- Use eco-friendly cleaning products.

- Use suitable materials for cleaning, like oil absorption wipes for cleaning the machinery and microfiber glass cleaning cloths for cleaning windows or glossy surfaces.

- Make sure your employees are trained in the proper use of hazardous chemicals and how to handle them safely.

- Ensure that all employees are adequately trained and use gloves when working with these chemicals.

- Ensure all employees follow company protocols for the safe disposal of waste materials (i.e., garbage).

What Type Of Wipes Can Be Used In Industrial Cleaning?

From the points mentioned above, you must have realized that cleaning wipes are also essential with the right cleaning procedure, practices, and equipment.

Therefore, when selecting a wipe for industrial cleaning, you'll want to consider a variety of factors, including the type of surface you're trying to clean, how much moisture the surface can withstand, and how easy the wipe will be for your employees to use, how much waste the wipe creates and how easy it will be to find replacements.

· Disposable Nonwoven Paper Towel

Disposable nonwoven paper towels often have a paper-based core coated with a thin layer of plastic to help create a more durable product. Paper towels have several advantages, including their low cost and ease of storage. However, they're not designed for use in extremely hot or cold temperatures, which may make them unsuitable for some industrial applications.

Nonwoven paper towels are a staple in almost every industrial cleaning kit. Paper towels are designed to be used once and then thrown away. However, their thin paper-based core and plastic coating give them a high moisture tolerance. They're suitable for almost all industrial cleaning applications.

Paper towels are great for wiping down workstations, floors, walls, counters, desks, equipment, and any other surface that doesn't require a higher level of cleaning. They're also suitable for wiping equipment or cleaning glass and windows.

· Oil Absorbent Clothes and Wipes:

If you're cleaning industrial surfaces that are often coated with oil, waxes, or other chemicals, you may also want to consider using wipes that are designed to withstand such conditions as Oil Absorbent cloth or wipes.

· Disposable Microfiber Clothes

Disposable nonwoven microfiber clothes are often much more expensive than paper towels, but they’re typically more durable. They are designed to be used repeatedly without needing to be washed after each use.

Microfiber clothes are made from a blend of polyester, polyamide, and polyethylene that's coated with a layer of polyurethane. This coating helps make microfiber towels durable and resistant to damage quickly.

Microfiber clothes are best at removing dirt, grease, grime, and oil from hard surfaces like metal, plastic, glass, and concrete. However, they don't do well at removing dirt from porous surfaces like wood, brick, and carpet and aren’t suitable for extremely hot or cold temperatures.

· Reusable Industrial Cloth

They can be used for almost any industrial cleaning application, but they're often more expensive than paper towels or microfiber towels and more challenging to manage.

These cloths are usually made from heavy-duty material with a textured surface designed to make it easier for employees to hold them and less likely to get tangled up in each other.

Industrial cloths are made from heavy-duty material that’s designed to be used over and over again without needing to be washed.

They're usually made from cotton, polyester, or polypropylene and are often dyed to a neutral color.

These cloths are often made from sturdy material resistant to damage from frequent use and easy to manage without tangling.

They're beneficial for cleaning windows, floors, difficult-to-reach areas, and delicate equipment like printers. Like disposable nonwoven paper towels, industrial cloths aren't designed to be used in extremely hot or cold temperatures.

Disposable Nonwoven zigzag microfiber glass cleaning cloth can also be used as an alternative to these reusable industrial cloths.

What Are Some Industrial Cleaning Uses For Wipes?

When it comes to industrial cleaning, there are a few specific applications where a particular type of wipe will typically be used over another.

- Food Processing Applications - Disposable oil absorbent cloths and wipes are an excellent choice for cleaning equipment, floors, and counters in a food processing facility. They're strong enough to withstand foods' moisture, acidity, and abrasiveness without creating too much waste.

- Sanitary Applications - Disposable microfibers are an excellent choice for sanitary applications like glass and car washing. These car cleaning towels are strong enough to withstand repeated washing without creating too much waste.

- Glazing Applications - Reusable industrial cloths and nonwoven zigzag microfiber glass cleaning cloths are the best choice for cleaning glass or glazing equipment in a manufacturing facility. These cloths are durable enough to withstand the abrasiveness of the glass while still being gentle enough not to scratch the surface.

Conclusion

When considering how to do industrial cleaning in your facility, you must consider the type of cleaning required. There are many ways to do industrial cleaning, including using high-quality cleaning wipes, high-pressure water systems, air deodorizers, and disinfectants.

When considering the best way to do industrial cleaning in your facility, you must ensure that it is efficient, cost-effective, and safe. You can make it easier by looking at the different industrial cleaning methods.

Besides, when it comes to industrial cleaning, disposable nonwoven paper towels, oil absorbent wipes, and microfiber clothes are by far the most common wipes used by most companies.

Before using any cleaning product, make sure to read the package and make sure it's suitable for the job you need to be done.

If you have any queries or are looking for high-quality industrial cleaning wipes, feel free to connect with us at HzxyNonWovens.com.