Disposable bed sheets can be made from a variety of materials, each providing their own advantages.

Disposable bedsheets roll are pretty commonly used for serving various purposes. If you look for them in the market, you will come across multiple options, and each will have a different material from which they must be made.

Since various materials are used in each disposable bedsheet when choosing them, it is imperative to exercise care. Primarily, such bedsheets are used at hospitals for patients to protect the bedding underneath the bedsheet from leaks.

Let's see what is bed sheet? https://en.wikipedia.org/wiki/Bed_sheet

For example Tencel fiber is soft and comfortable but it is very expensive and will wear down over time while hydrophobic spun-bond polypropylene provides stain resistance as well!

Moreover, at the hospital, patients have different kinds of viruses and diseases, so to avoid their transmission, disposable bedsheets are used so that they can be thrown away after using them once.

One of the biggest concerns many people may have when choosing a disposable bedsheet is the material selection. It is vital to select a suitable material that is free from causing any skin rash or allergy and offers a leak-proof solution.

However, if you are wondering which is the most suitable material for choosing to produce disposable bedsheets, you should look forward to PP spunbonded nonwoven fabric. This fabric is not only comfortable for people who sleep over it; it also has various other benefits that add ease to the user's life.

If you want to know more about this material and how it could be the right choice, you should keep reading below.

https://hzxynonwovens.com/product/disposable-white-nonwoven-perforated-bed-sheet-rolls/

How are Disposable Non-Woven Sheets Produced?

Let's see how dose the polypropylene spunbond nonwoven fabric made?

After the polymer has been extruded and stretched to form a continuous filament, the filament is laid into a web, and the web is then bonded by itself, thermally, chemically or by mechanical reinforcement methods to turn the web into a nonwoven fabric.

Spinning fusion is the most widely used one-step spinning and forming process for forming nonwovens. The key steps are melt spinning, primary fiber air stretching, fiber web formation and fiber web sizing.

Spinning fusion nonwovens are formed with continuous filament fibers, with high production line speed, high product strength and good dimensional stability.

Non-woven disposable bedsheets are produced by forming a web of fibers. This web is created by entangling and joining the threads in the web, and lastly, finishing is carried out to ensure the unique properties are added to the fabric as required.

These steps below will explain to you how the manufacturing of such sheets is carried out.

Formation of Web

The fiber material is very soft and flexible, hence suitable for such bedsheets. The process of web formation is dependent on the length of the fiber. The fiber having a long length is treated with the carding process. However, the short fibers are converted into webs through a papermaking process called the wet-laid procedure.

The mechanical strength of this fiber web is not strong enough to serve the purpose of being a disposable bedsheet. Hence, other processes add some properties to the sheets after forming these webs.

Bonding of Web

The next step is bonding the web of fibers through spunbonded punching. This way, the fibers in the web are locked with one another. There are different kinds of bonding, the first one being stitch binding, in which the fiber is knitted with one another.

The next kind of bonding is thermal bonding; in this process, the web is treated with heat to bind the web structure. In chemical bonding, a chemical binder adds stiffness to the fiber web so that the sheet gains some strength.

Another commonly used method for the production of non-woven disposable bedsheets is known as hydroentanglement. In this process, a special fluid is used to bind the fibers. This fluid causes the fiber to entangle appropriately and gain strength.

Final Finishing Process

When the non-woven fabric bedsheets have been passed through the above processes, the final finishing is the last stage carried out. In this stage, the process of lamination, coating, and embossing is carried out.

The finishing stage adds different properties to the bedsheet to ensure whether these bedsheets are used for treatments in medicine where they need anti-stat and anti-microbial properties or the ability to retard flames. The final stage of finishing helps convert the bedsheets according to the customer's specifications.

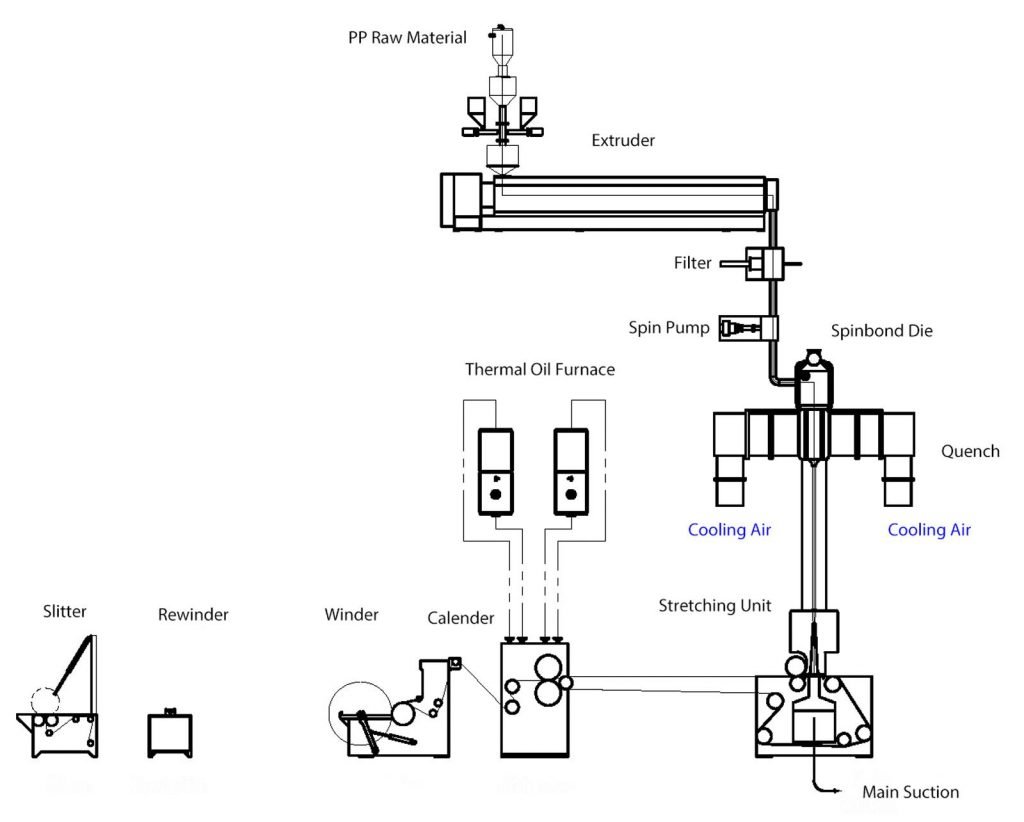

Please check the following image of manufacture procedure.

How do unqualified disposable non-woven sheets affect use and harm health? What is the suitable fabric for disposable non-woven sheets?

There are always quality issues with all kinds of fabrics. Some fabrics are of the best quality, whereas some have an inferior quality that harms the health of the user. Similarly, if the disposable non-woven sheet is not of good quality, many harmful impacts are caused, some of them include the following:

- Many fabrics cause rashes on the skin due to being rough. This roughness in these fabrics is because of the fibers used since they are treated with chemicals. The chemical formaldehyde is one of the most irritating chemicals used in fabric-making and causes skin abrasions.

- Also, many disposable non-woven bedsheets are manufactured using crease-resistant chemicals, and such chemicals have urea-formaldehyde in their making. This could irritate the eyes, throat, and nose of the user.

Hence, compared to choosing these unqualified fabrics, it is suggested to opt for PP spun-bonded material. This fabric is manufactured by binding the chemicals through a lamination process; hence the impact of chemicals is never harmful to the user.

PP Spunbond fabrics are soft and breathable. Therefore the user does not feel any roughness or irritation while using them. Since these disposable sheets are used mostly at hospitals for patients, much care is exercised when manufacturing them. They are waterproof and offer antibacterial and non-toxic material.

Avoiding Defects in Non-Woven Fabric for Disposable bedsheets

It is imperative to choose a non-woven fabric for disposable bedsheets that is defect free. If the material has flaws, the sheet will also have those defects, which might deteriorate its quality. It is significant for these kinds of bedsheets to be of good quality.

Various kinds of defects may be present in the fabric and could be avoided as well. Sometimes there is a crack in the fiber's length, which could be avoided by ensuring that when subjected to the sizing machine, the beam surface is not uneven.

The issue of double ends in the fabric is also common and could be avoided by ensuring appropriate size measurement when the stitching process is carried out. Sometimes there are also fine cracks in the fabric, and this causes warp tension in the bedsheets. It could be avoided by ensuring the tension of the warp.

Uneven slabs could also cause a defective sheet, so adjustments must be made during the spinning process. The defects can quickly be curtailed in such bedsheets during the process of manufacture. The flaw lies in the fabric sometimes and hence can be handled by keeping an eye on it before the process of manufacturing starts.

How to detect whether the disposable non-woven bedsheets you buy are defective?

Examination of non-woven disposable bedsheets will help you detect if these bedsheets are defective or not. There are various aspects that you may keep in mind when choosing these bedsheets, and some of these defects that need to be taken into account when buying them include the following:

- These bedsheets aim to be absorbent enough, so if your selected bedsheet cannot absorb fluid and it ends up leaking it to the under area, it's no use.

- Since these bedsheets are disposable, you must dispose of them sooner or later. However, they still should be durable. You never know for how long you might end up using them for one patient, so they should also stay intact for longer-term use.

- The bedsheet must be adequate to cover the entire bed area. Unusual sizing and mismatched ends are also forms of defects in such bedsheets that must be avoided.

- If the bedsheet is rough, it will cause skin abrasion to the user. Therefore, the softness and thread count of these disposable bedsheets must be considered.

Which countries have the highest quality requirements for disposable non-woven bedsheets?

Many countries have quality concerns for disposable non-woven bedsheets. The primary producer of these bedsheets is China. At the same time, the demand for these bedsheets extends to the USA, Germany, Bangladesh, Australia, and many countries across the globe.

China is the leading supplier of these bedsheets all over the globe, and the quality is always top-notch, ensuring comfort and the best quality fabric used for manufacture.

Summary

When choosing non-woven disposable budgets, it is imperative to know your specifications. If you are looking forward to having hands on a waterproof bedsheet, then two layers of PP spun-bonded fabric will be needed.

This bonding of two layers will add waterproof properties to the material and could be easily used for hospital patients. No liquid will pass through such bedsheets, adding a lot of ease for the users. Hence, there is a purpose for such bedsheets to serve and therefore different varieties are manufactured.

Waterproof bedsheets are pretty popular in hospitals and need to be of the finest material. The PP spun-bonded fabric is a great quality fabric for this purpose. However, such disposable bedsheets may also be required for other uses, such as using them in salons. So, when such bedsheets are needed for salon use, a single layer of PP spun-bonded material would be suitable.

You must have understood all the details regarding non-woven disposable bedsheets and how important it is to choose the right kind of bedsheet and undo the defects they might have.

Also, assessing the need to use such bedsheets is also equally important; this will help you determine the properties you expect in such bedsheets according to your use.