Woven Vs. Non-Woven Microfibre: A Detailed Comparison

Microfiber is a type of textile made from tiny synthetic fibers. It is used in a wide array of applications, including as upholstery fabric, towels, clothing, cleaning, filters, and insulation. Microfibres can be made from different materials, including polyester, nylon, and polypropylene.

Microfibre can be divided into two main categories: woven and non-woven. Woven microfibre is made by weaving together individual fibers. Non-woven microfibre is made by bonding individual fibers together with heat, pressure, or chemicals.

Each type of microfibre has its own benefits and shortcomings. In this article, we will compare woven vs. non-woven microfibre in detail to decide which type is right for your needs.

Woven Vs. Non-Woven Microfibre – Which One Is Better?

Both Woven and Non-Woven Microfibre cloths are better in their way! Janitorial cleaners usually use woven Cloths to pick up dirt, food, and moisture. In contrast, non-woven are good at picking up bacteria and preventing cross-contamination, so they are widely used for healthcare and food services.

Apart from the differences mentioned above, Woven and Non-Woven Microfibres differ in many ways. Keep on reading to explore!

Is Microfiber A Non-Woven Fabric?

Microfiber cloth can be both woven and non-woven fabric.

Microfiber cloth is often classified only as non-woven fabric, but this is technically incorrect.

Non-woven fabrics are made by bonding fibers mechanically, chemically, or thermally, without weaving or knitting.

Microfiber cloth can also be made by weaving or knitting together very fine fibers, so it can technically fall into any category among non-woven, woven, or knitted fabrics. However, microfiber cloth is often grouped with non-woven fabrics for ease because of its unique properties.

What Is Microfiber Made Of?

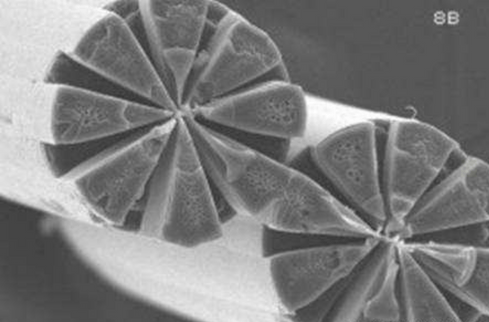

Microfiber is a type of synthetic fabric made from extremely fine fibers of polyester, nylon polymers, wood pulp, polyamide, or their combination.

The fibers are typically less than one denier in diameter, about 1/10th the diameter of a human hair. Microfiber fabrics are lightweight and soft and have a very high absorbency rate. Besides, they are less prone to wrinkling and shrinking.

They are used to make a variety of different products, including clothing, towels, mats, knits, weaves, and upholstery.

What Is Non-Woven Microfiber Made Of?

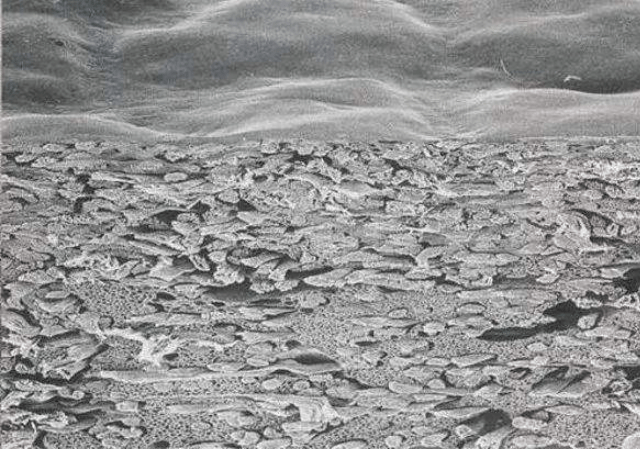

Non-woven microfiber fabric is made from a blend of microfibers that are bonded together by heat, chemical, mechanical, or solvent treatment. The fibers are typically synthetic, but natural fibers are also used.

What Are The Different Types Of Microfiber?

Microfibers can be classified into various types depending on their material, characteristics, and production method. Some of the notable microfiber types are as follows:

- Split-weave microfibre: This microfiber fabric features countless tiny loops on the fabric's surface that clings to your skin when touched. These loops are formed due to the fiber splitting process during production. This clinging feature is due to a positive charge that helps attract naturally negatively-charged materials like dirt, making this microfibre type suitable for making microfiber cleaning cloth.

- Ultra-Suede: It is a type of non-woven microfibre made from polyester fibers. It is considered an artificial alternative to suede leather. It has a smooth surface that feels soft to the touch. Ultrasuede can be used for clothing, towels, sofa, couch, and rugs. It is stain resistant, machine-washable, and doesn't lose color easily.

- Flat-weave microfibres: They are made from polyester fibers bonded together into a flat sheet. These types of fibers are usually used for glass cleaning. They're water-repellent and less absorbent than split-weave microfibers. They don't offer as much protection from water damage as other types of microfibers when exposed to water.

- Microbial: It is another type of microfiber fabric similar to Ultrasuede but has tiny strands in the weave that make it easier to clean small spaces. It is made from nylon fibers that have been chemically treated to make them more durable and resistant to water damage. However, compared to polyester-polyamide, these Microbial microfibres are less durable and stretchy. They work well on delicate surfaces such as marble and granite countertops or wood flooring.

- Prolen: It is a microfibre fabric made of extremely fine fibers of polyester. These fibers are so tiny that they are invisible to the naked eye. Prolen microfiber is known for being incredibly lightweight, breathable, and resistant to wrinkles and static.

6. Terry microfibre: It is a type of microfiber fabric that is made from extremely fine fibers. This makes it incredibly soft and absorbent, making it suitable for microfiber towels and other clothing items that need to be gentle on the skin. Additionally, the Terry microfibre is resistant to wrinkling and fading, making it a durable option for various uses.

7 Waffle weave microfibre: It is a type of microfiber fabric made from very thin fibers woven together in a waffle-like pattern. This raised and unique pattern reduces the contact with the surface, decreases friction, and enhances the gliding movement, making it suitable for glass cleaning. This fabric is also highly absorbent and can be used for countless applications related to cleaning and dusting.

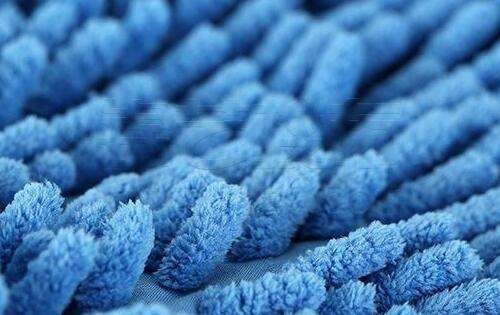

8 Chenille microfibre: It is a microfibre fabric type made from extremely thick, finger-like protrusions of fibre held together to a thin fabric base. These fibers are often made from synthetic materials such as nylon or polyester and are tightly woven together to create a soft, velvety surface with plush strands. Chenille microfibre is often used for cleaning purposes like sponges, car washing microfiber towels and car wash mitts.

- Suede Microfibre: It is a man-made version of suede leather made from thousands of fine microfibers to give a natural suede-like texture and feel, making it much less problematic than genuine suede leather. It is soft, resistant to wear and stain, and lightweight. It is used to make curtains, bedding, shoe, and other fashion accessories.

Apart from the types above, microfibre can also be classified by its material and production type; Woven, Non-Woven or Knitted.

What Is the Difference Between Woven VS. Non-Woven Microfibre?

Woven microfiber is made from threads that are woven together, while non-woven microfiber is made from fibers that are matted or bonded together.

Following are some of the notable differences:

- Woven microfiber is stronger and more durable than non-woven microfiber, making it ideal for cleaning surfaces prone to scratches or abrasions. However, non-woven microfiber is more absorbent than woven microfiber and is better suited for cleaning up spills.

- Woven microfiber leaves lints on the surface after cleaning, whereas linting is considerably low in non-woven microfiber.

- Woven microfibers are good in cleaning notable dirt and moisture, whereas non-woven microfiber is excellent in picking up bacteria and reducing cross-contamination. Therefore, non-woven microfiber is recommended for food and medical services and approved by FCC (Food Contact Clearance).

- Woven microfiber may leave streaks behind on glossy and delicate surfaces like glass. In contrast, non-woven microfiber is excellent for polishing and sparkling the glass and stainless steel surface without leaving any marks, smears, or streaks.

- Woven microfiber can be washed and reused multiple times, whereas non-woven microfiber is usually disposable and non-washable.

Applications of Woven and Non-Woven Microfiber Cloths:

The applications of microfiber cloths are endless.

Application of Non-Woven Microfiber:

Non-Woven microfibers are very good at picking up bacteria, and reducing cross-contamination. Besides, they are also great at cleaning delicate surfaces like glass without leaving any mark, smear, or streak, so they are usually used for hygienic and disposable applications as well as for polishing and glass cleaning, including:

- Absorbent hygiene products (AHP): They can be used to manufacture Baby diapers, adult incontinence products and feminine hygiene products.

- Medical: They are used to manufacture wide array of medical accessories, including Disposable caps, gowns, Bed linen, masks, scrub suits and shoe covers, Drapes, wraps and packs, Sponges, dressings and wipes, Lab coats, Shrouds, Under-pads, Procedure packs, Ostomy bag liners, Sterilization wraps, Wound care, and Cold/heat packs.

- Household: Cleaning Wipes, Abrasives, Flooring, Bed linen, Carpet/carpet backings, Blinds/curtains, Covering & separation material, Vacuum cleaning bags, Detergent pouches/Fabric softener sheets, Furniture/Upholstery, Mops, Table linen, Tea and coffee bags, and Wall-covering.

- Personal Care: Baby wipes, Medicated wipes, Feminine Hygiene wipes, Facial wipes, Hand & body wipes, Cleansing wipes, Moist towelettes, Personal Hygiene wipes, and Antibacterial wipes.

They can also be used for various Agriculture, Horticulture, Automotive, Building, Geotextile, and filtration-related applications.

Application of Woven Microfiber:

Woven microfiber fabric is a very strong and durable material that can be used in countless ways. However, it should be pondered that not all microfiber cloths have the same properties and each type is designed for specific applications.

- Clothing: Microfiber fabrics are used for athletic apparel like cycling jerseys, as their moisture-wicking property wicks the moisture and helps evaporate it to keep the wearer's body cool. Besides, microfiber fabric's high durability, strength, and elastic properties enable the garment to hold its shape and prevent wear and tear. Moreover, some types of microfiber cloth are soft, stain-resistant, and a good water absorbent, making them perfect for underwear, bathrobes, and swim trunks.

- Fashion Accessories: Microfibres, especially suede and Ultrasuede microfibers, are used to make fashion accessories like handbags, shoes, wallets, and phone cases, as they are used as a replacement for natural suede leather.

- Textile for Cleaning: Microfiber is widely used in this industry. They can be used to clean or polish furniture, cars, windows and mirrors, and even your dishes. Microfiber cloths are so soft and absorbent that they can be used on many surfaces without leaving any marks or scratches on the surface. They can also be used to scrub bathrooms, clean appliances, and kitchen counters.

- Microfiber cloths are also great for applying makeup, cleaning glasses and lenses, dusting, polishing, and more. They are also highly absorbent and can be reused many times over.

- Microfibres can be used to make curtains, bedding, and upholstery like sofa covers, etc.

- They can be used as microfiber wipes in medical applications in hospitals and clinics.

- Microfibres are also used in manufacturing industrial filters, mats, knits, and weaves.

Pros and Cons of Non-Woven Microfiber Cloths

Non-Woven microfiber cloths have various advantages and disadvantages depending on their type, microfiber material, and production method.

Pros:

- They're easy to use, and they're gentle on your skin.

- They're also great for cleaning glass, mirrors, and other hard surfaces—and because of their thinness and softness, they don't leave any streaks behind on the surface you're cleaning.

- They are readily available. You can easily find them in stores, online, or in bulk from reliable manufacturers like Hzxynonwovens.com.

- They trap and hold dirt, dust, and 99.9% of bacteria, efficiently removing these particles from surfaces.

- The non-woven microfibers have low lint, so they won’t leave any microfibers on the surface after cleaning.

- Microfiber for glasses wipes

- Disposable non-woven microfiber cloths are environment-friendly and biodegradable.

- The production of non-woven microfiber cloths can be controlled to achieve specific properties, soft, water repellent, antibacterial, hypoallergenic, breathable, tough, and absorbent, to make it ideal for a particular application.

Cons:

- They can be expensive compared to traditional cotton or polyester cloths.

- A few types of non-woven microfiber cloths, especially the ones made from polyester, are highly flammable and tend to release harmful gasses if burned.

- Non-woven microfiber clothes that are non-disposable are usually non-biodegradable too.

- They are less durable and less strong than woven microfiber cloths.

- They are difficult to wash.

- They are quite easy to tear.

Final Words,

The points mentioned above prove that both woven and non-woven microfiber are good on their own, depending on the application. You only need to consider your application and the source to buy them.

Although there are many manufacturers, we suggest you try hzxynonwovens.com. They are pioneers in producing the best microfiber cleaning cloths, and other types of non-woven fabric and wipes for your needs.